Friction and Lubrication

Some times there is screeching sound while using a pulley or hand

pump. Friction is a force. Whatever work we do, friction works opposite

to our force. When we apply a force to move something, the friction

opposes our force and there is no motion. When our force is greater than

the friction force, the object starts moving. The parts where there is

friction, they wear out fast.

A smooth surface shows lots of uneven and rough surface under a

microscope. When these rough parts rub on each other, it results in

friction.

Oiling and greasing reduces friction and wear & tear of parts. When

there is dust or foreign particles in the area of contact, friction and

wear & tear are high and rapid. To prevent this, we must first clean

the friction area and put oil or grease there.

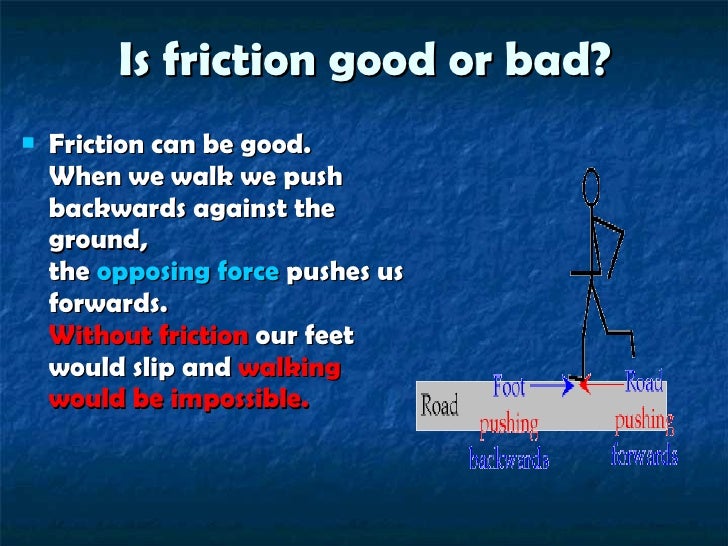

Friction is not always bad. Sometimes we require friction.

For

example:

1) While walking friction helps us. If we put oil on the floor, we will

fall down due to slippery floor. We need friction to be able to walk.

2) It is commonly seen that in muddy area the wheel of a truck slips

round and round because there is no friction between the tyres and

ground.

3) Flour mill works because of friction between belt and wheel.

4) Bicycle can be stopped by putting on a brake, which works because

there is friction.

5) When we tie a knot in a rope, it is the friction which holds the

knot.

Thus friction is useful to some extent but it will reduce the efficiency

of work.

Factors affecting friction

The intensity of friction depends on following factors:

i) The area involved in friction.

ii) The pressure applied on the surfaces.

Force = Pressure ´

Area

Frictional force will increase, if the area of contact will increase or if pressure applied on the surface increased.

Methods to reduce friction

i) Polish the contact surface.

ii) Put oil or grease so that it fills in the small gaps of the flat parts.

iii) Use ball bearings to reduce area of contact between rotating parts.

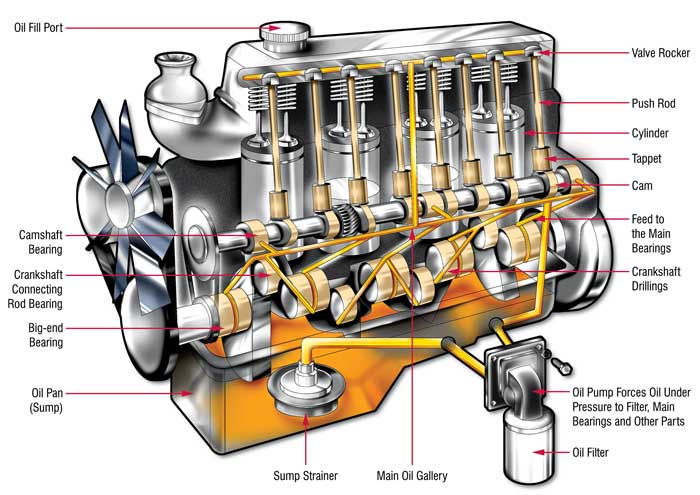

Lubrication

Following methods can be used to reduce friction:

Oil is either thin or viscous. It depends upon SAE No. of oil. (SAE means Society of Automotive Engineers). If we use very viscous oil, it does not reach all the parts. Very thin oil will flows away easily and gets wasted. Grease is used in such cases. It is generally used around ball-bearing. Normal grease or oil is never used where there is high pressure, high temperature and high speed. Special lubricants are used in such cases. In cold season the oil becomes thick and in hot season it becomes thin. Therefore selection of lubrication also depends on the season. It is always advisable to refer operating manual of the equipment before selecting the lubricant.

No comments:

Post a Comment